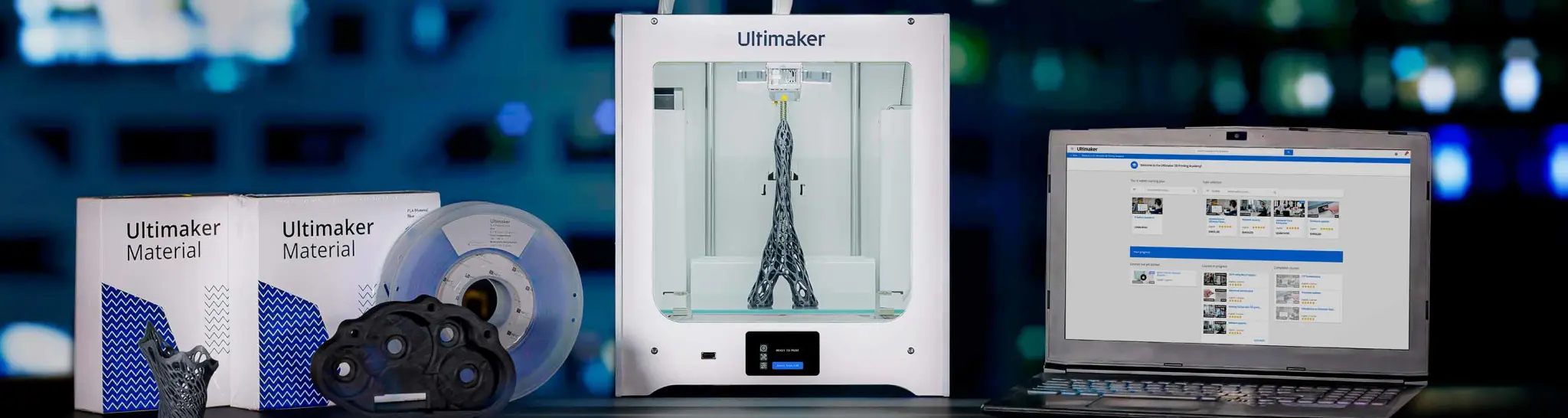

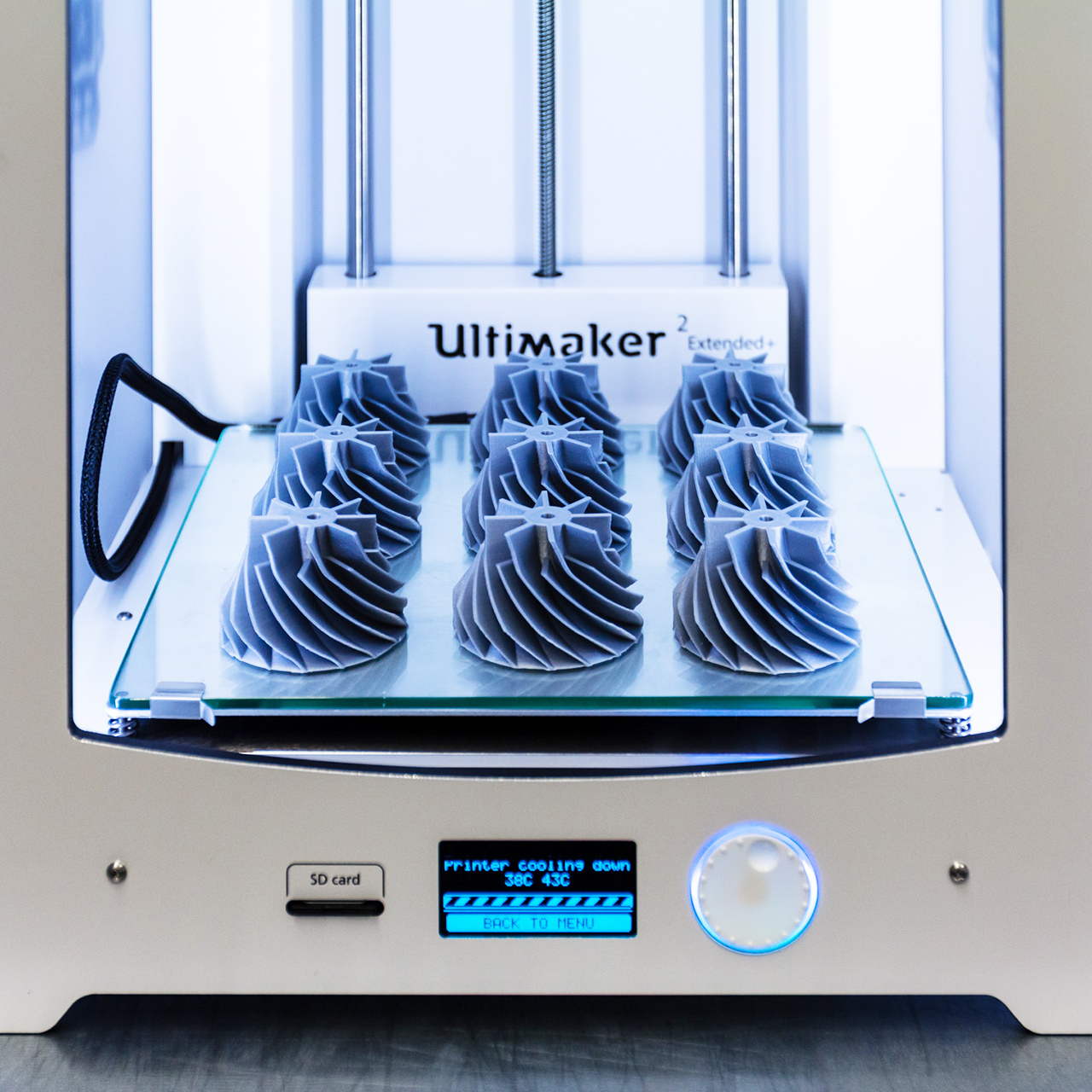

In our first ever Ultimaker Showcase event, we shared our latest progress across the entire Ultimaker product range. Read the blog '4 key updates from the Ultimaker Showcase' to learn more about the new products introduced during the event.

3D printing is an innovative technology that lets you create a physical object from a digital model. It started in the '80s under the name ‘rapid prototyping’ because this was the purpose of the technology: to prototype faster and cheaper. A lot’s changed since then, and today 3D printers offer amazing results and let you create anything you can imagine.

3D printing is also called additive manufacturing, because unlike the traditional subtractive manufacturing, 3D printing doesn’t remove material, it adds it, layer after layer. In order to print something, first you’ll need a 3D model of the object you want to create, which you can design in a 3D modeling program (CAD - Computer Aided Design), or use a 3D scanner to scan the object you want to print. There are also more simple options, like searching online on Youmagine.com for 3D models that have been created and shared by other people.

Once your design’s ready, all you need to do is import it into Cura, our open source print software. Cura will then turn your design into a gcode file ready to be printed as a physical object. Simply save your file to the supplied USB stick and insert it into your Ultimaker and press print.

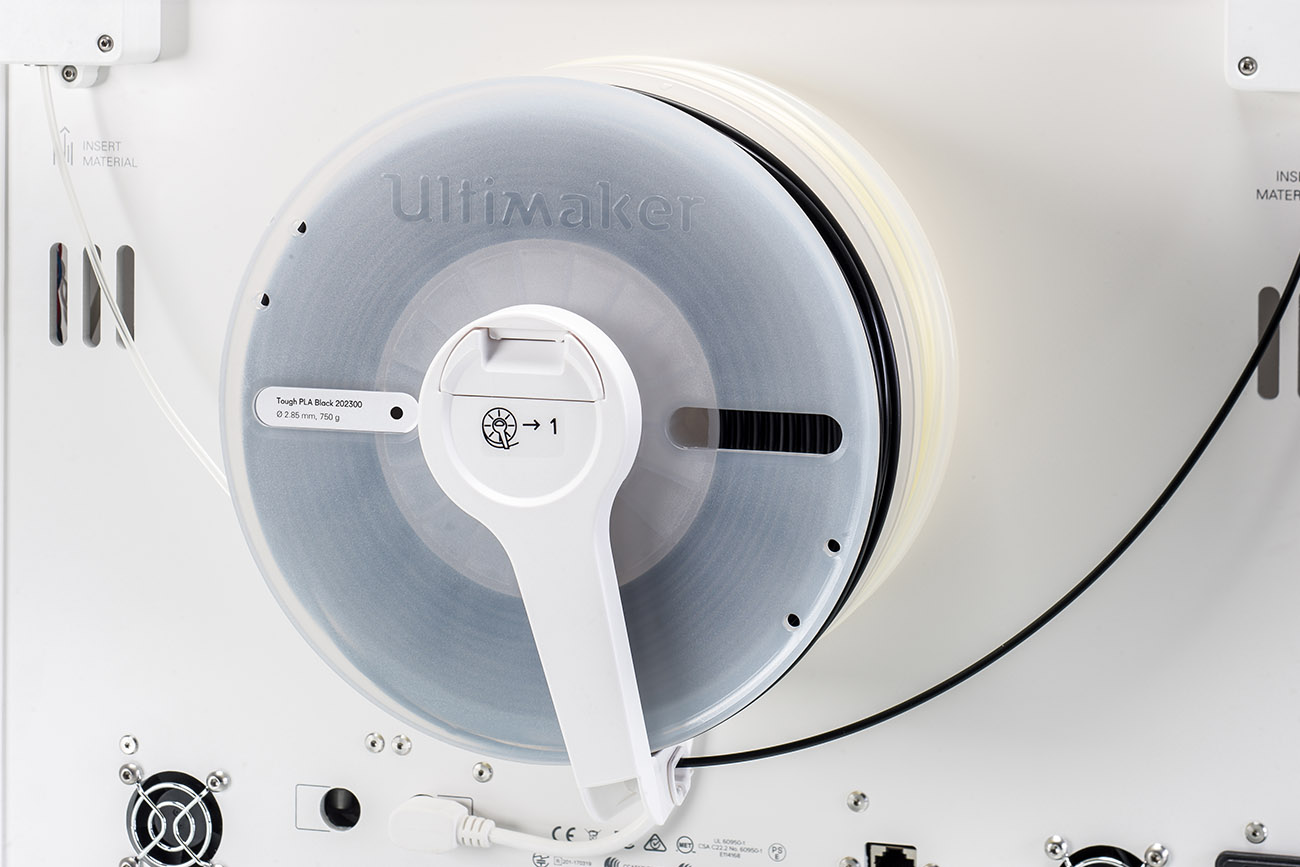

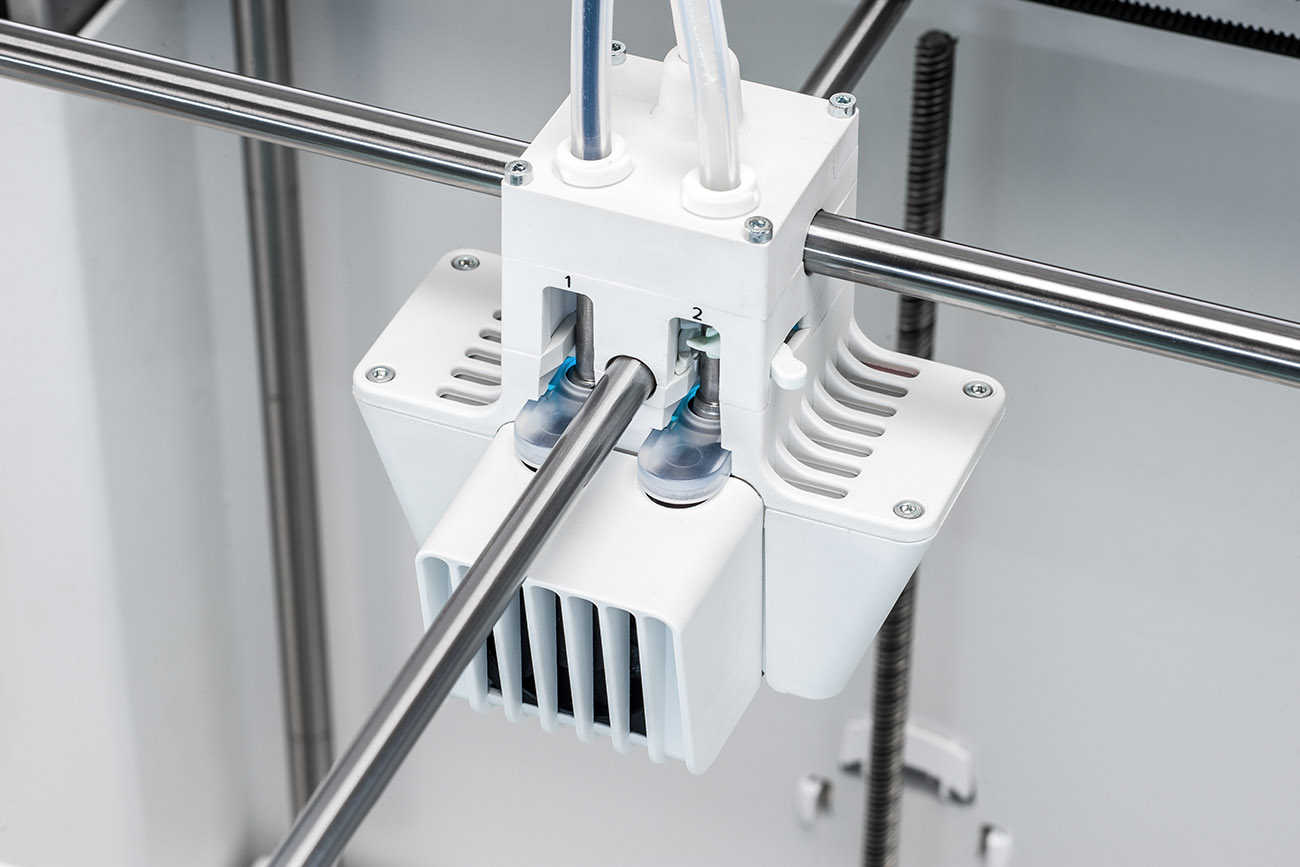

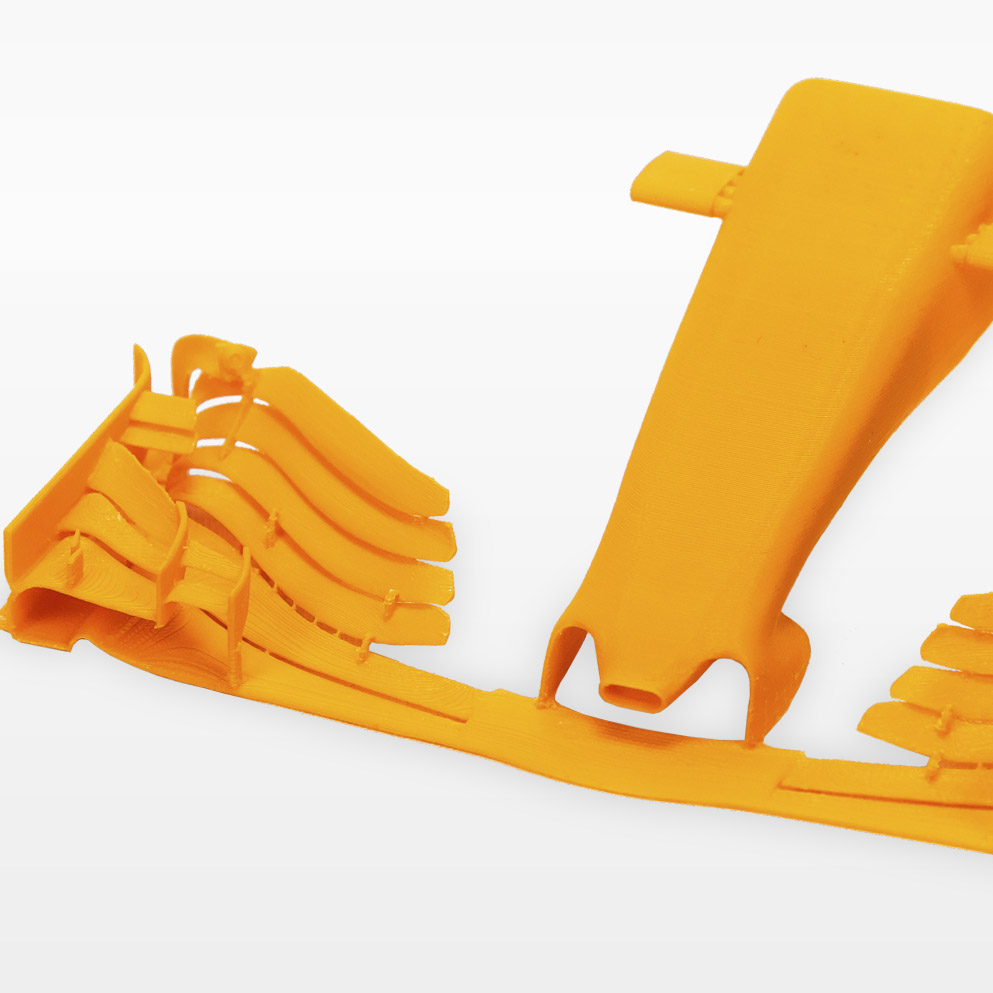

But how does the printer work? Although there are several 3D printing technologies, most of them create the object by laying down many successive thin layers of a material. Usually, desktop 3D printers use plastic filaments (A) which are fed into the printer by the feeder (B). The filament is melted in the print head (C) which extrudes the material onto the build plate (D) creating your object layer by layer. Once the printer starts printing, all you have to do is wait – IT'S THAT EASY.

Of course, when you become an advanced user, playing with the settings and tweaking your printer can lead you to even greater results.

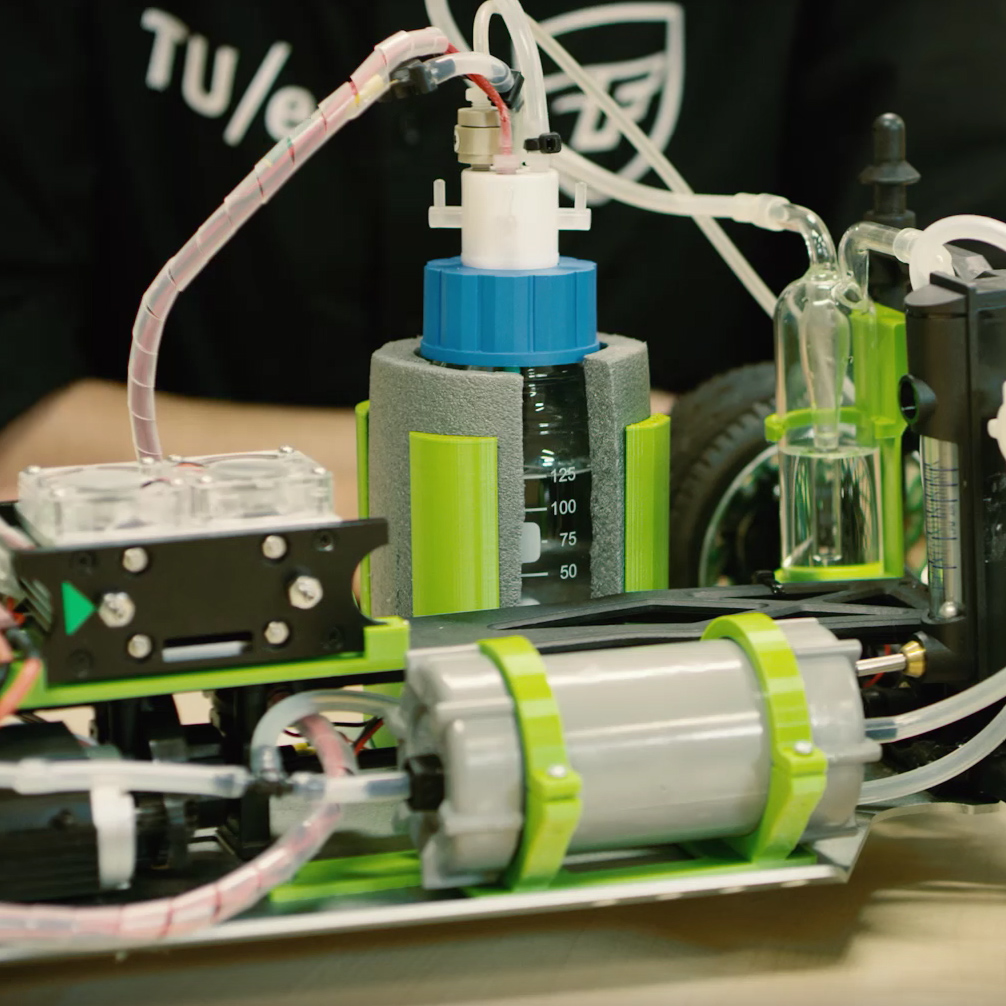

Create customized products that are completely tailored to your needs in terms of size and shape. Make something that wouldn’t be possible with any other kind of technology.

3D printing makes it possible to quickly create a model or prototype, helping engineers, designers and companies to get iterative feedback on their designs in a short time.

Models that are difficult to even imagine can be created in a 3D printer with ease. These models are great at educating others about complex geometry in an interesting and useful way.

The cost of 3D printing end use parts and prototypes is low thanks to the materials and technology used. Production time and material waste are reduced too as you can print models multiple times using only the material needed.