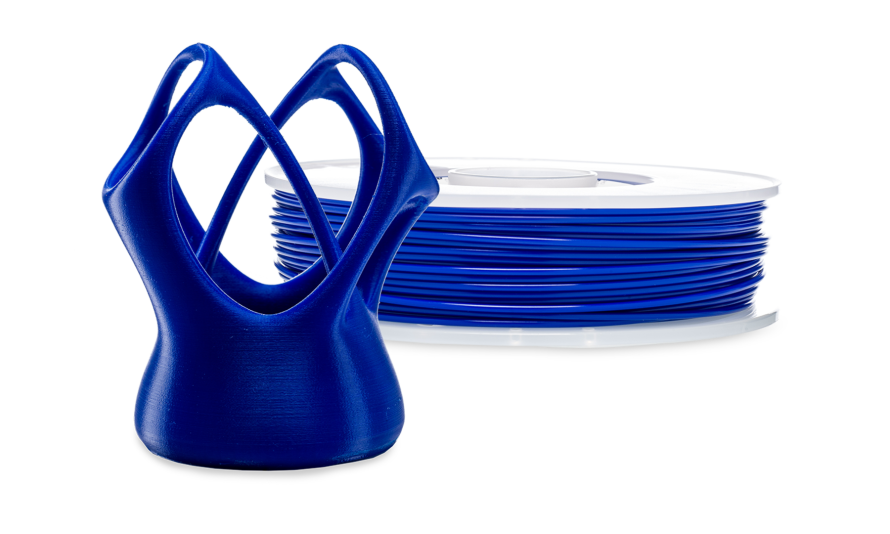

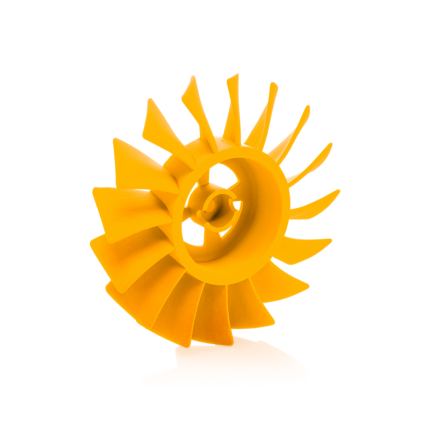

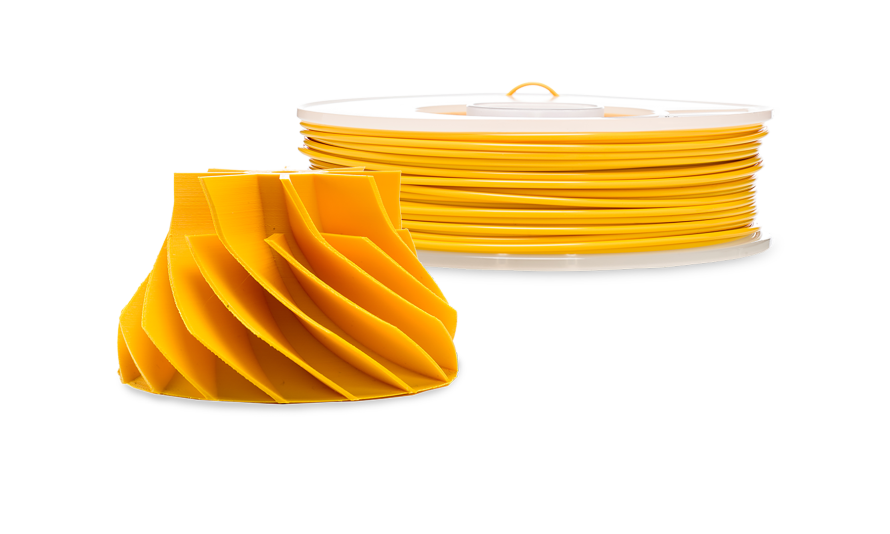

Ultimaker PLA (polylactic acid) is highly versatile, easy to print, and available in 11 colors. It prints reliably with high dimensional accuracy and a quality surface finish. This makes it an ideal material for a range of applications – from detailed prototypes to simple manufacturing jigs and gauges.

Ultimaker PLA’s versatility makes it the go-to material for a range of applications, including prototyping and concept visualization. Create detailed two-color prints, or combine with Ultimaker PVA for complex geometric features and complete design freedom.

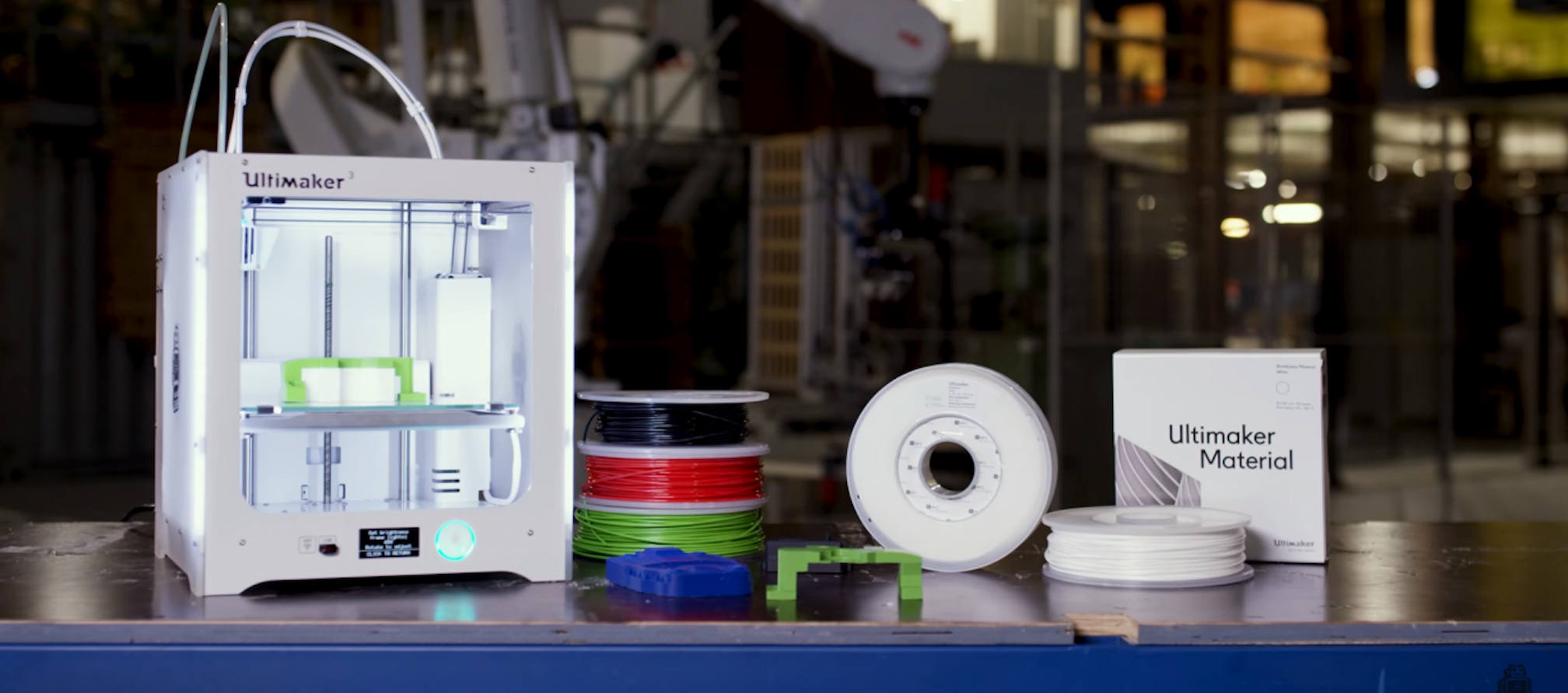

Ultimaker PLA helps architects quickly build affordable, high-resolution models with sharp surface details for client presentations.

With Ultimaker PLA, you can create detailed metal or ceramic parts with perfect accuracy. The plastic’s low melting point means it is ideal for investment casting and for mold inserts.

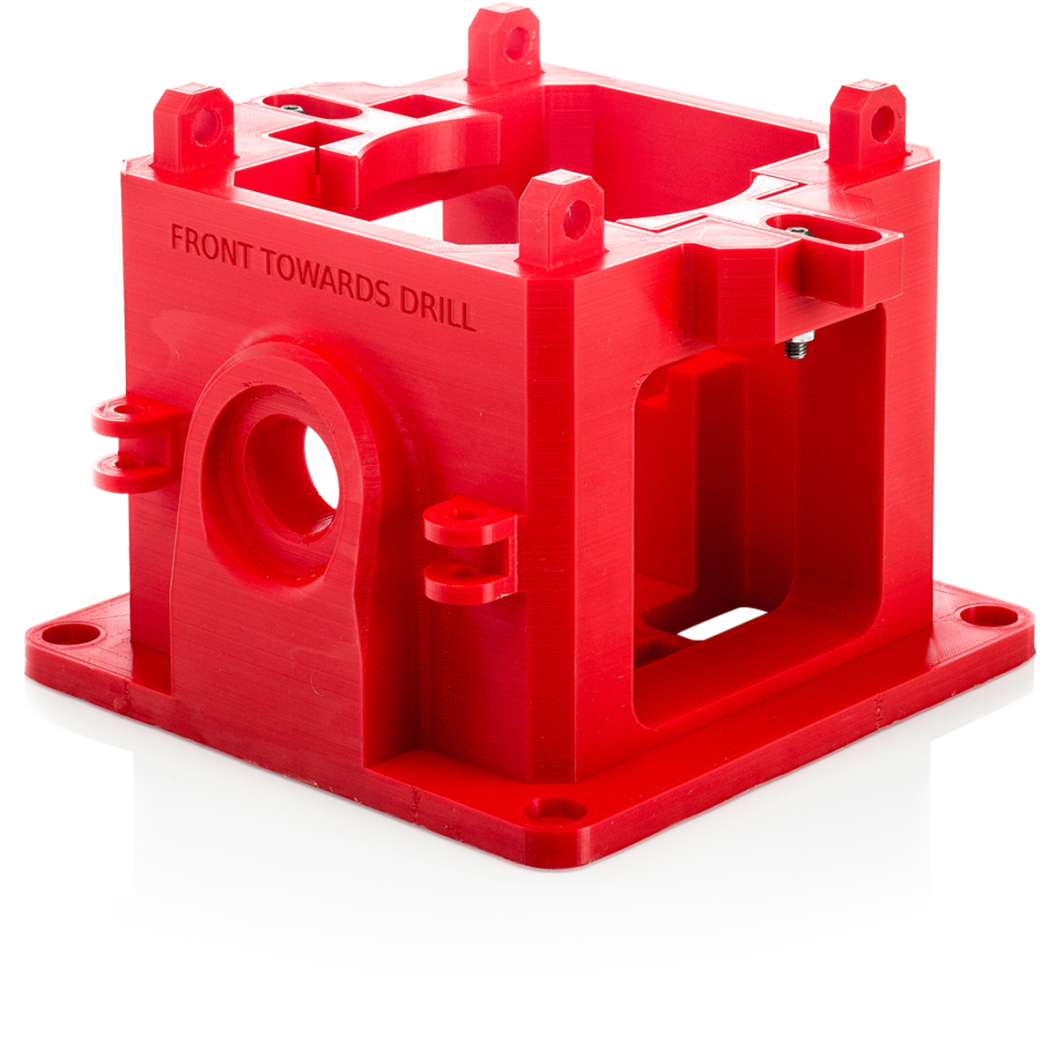

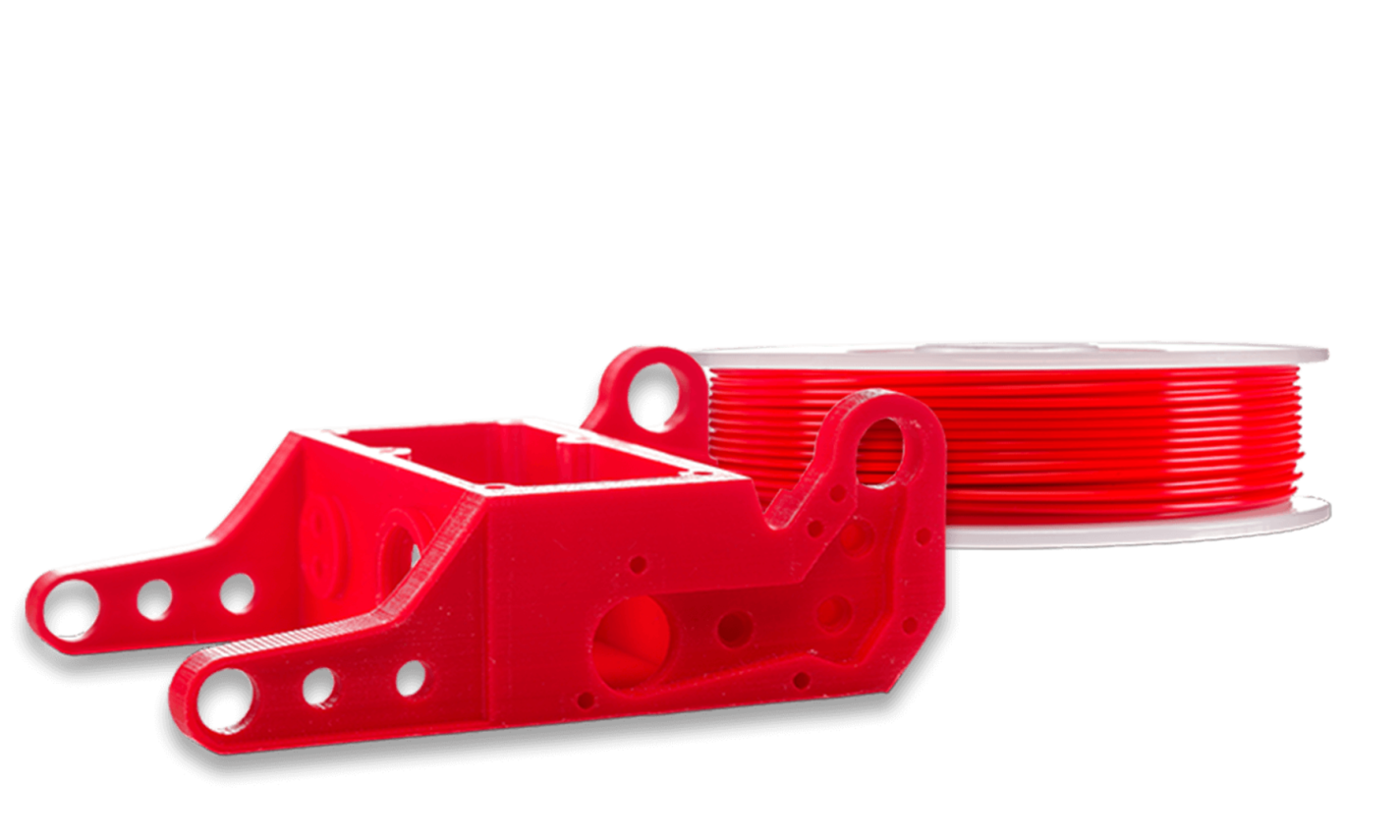

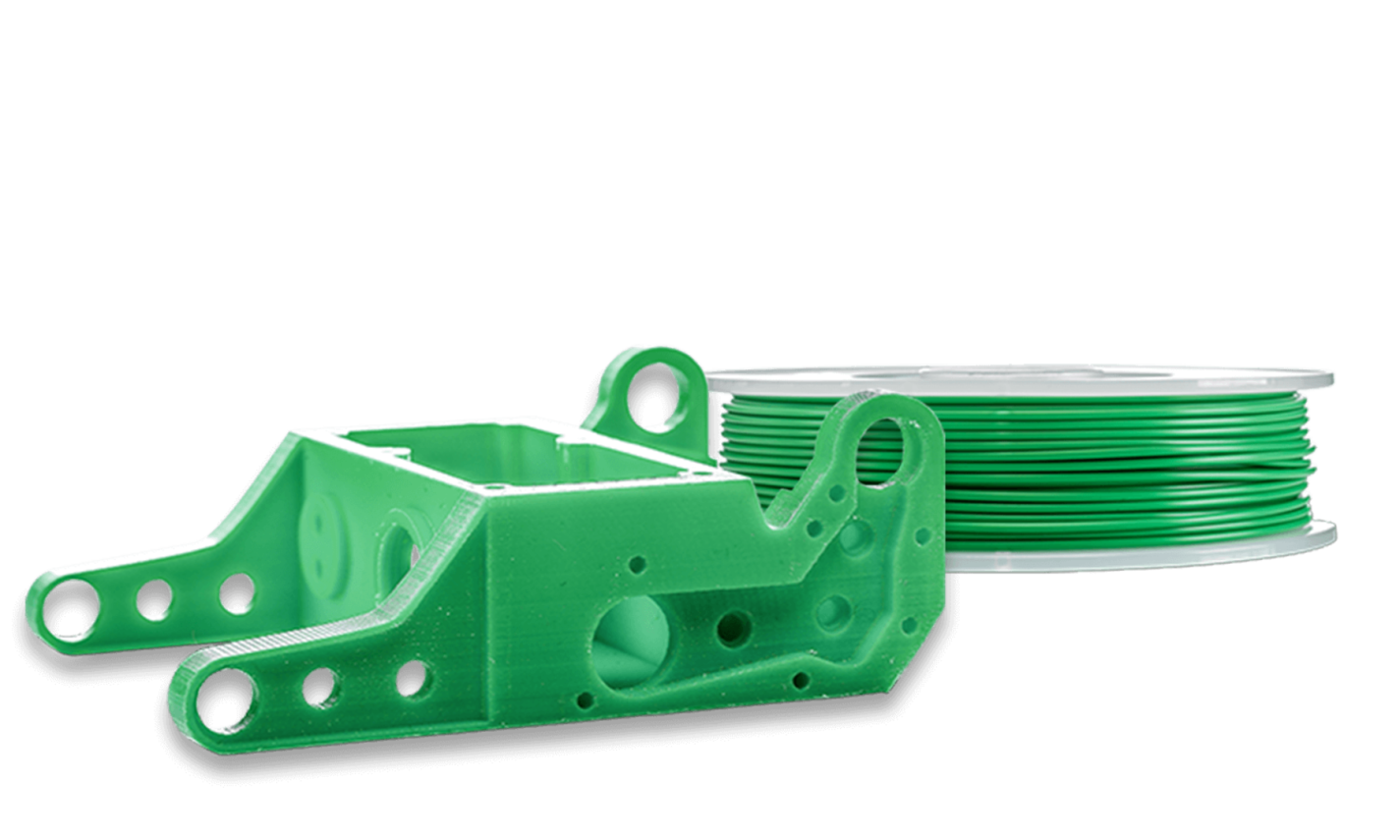

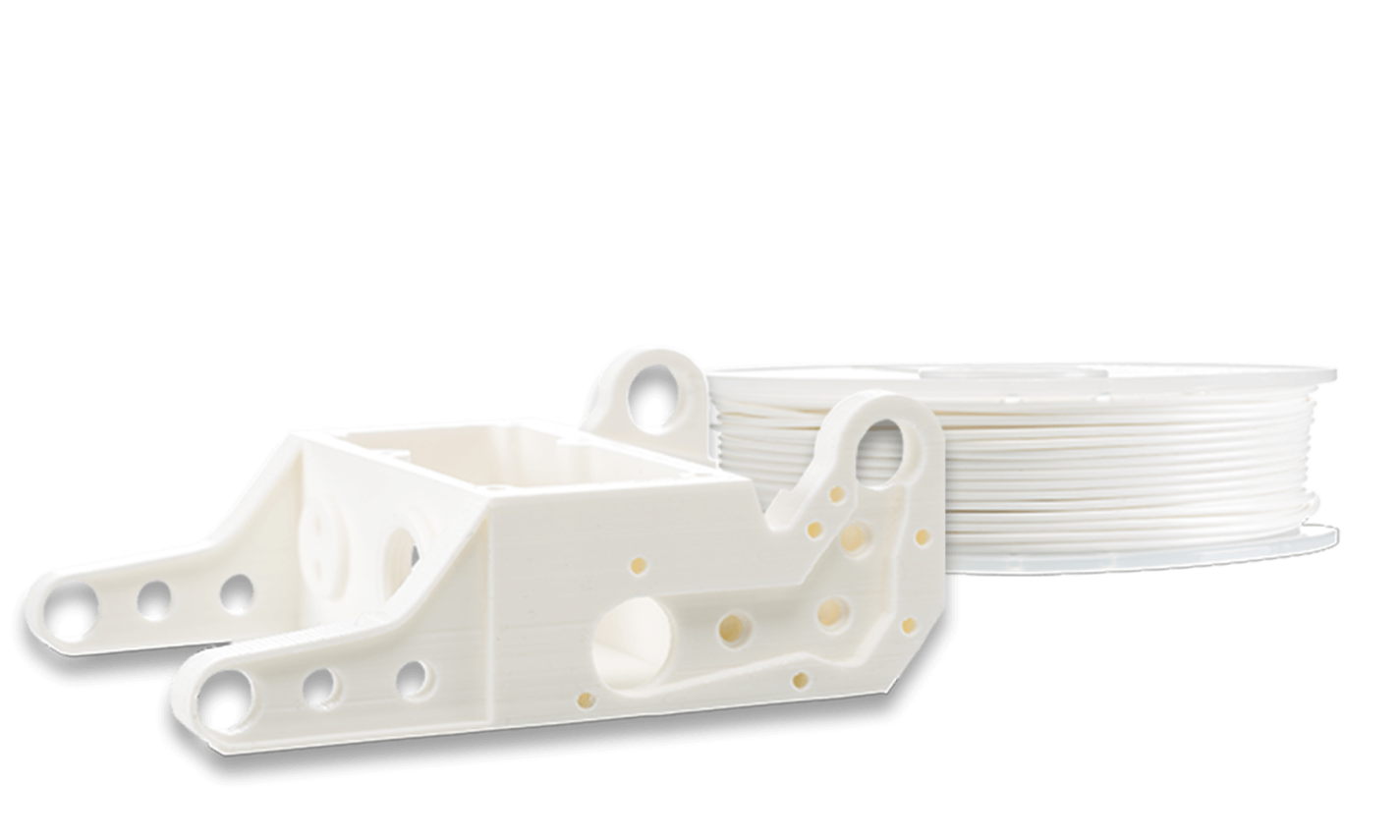

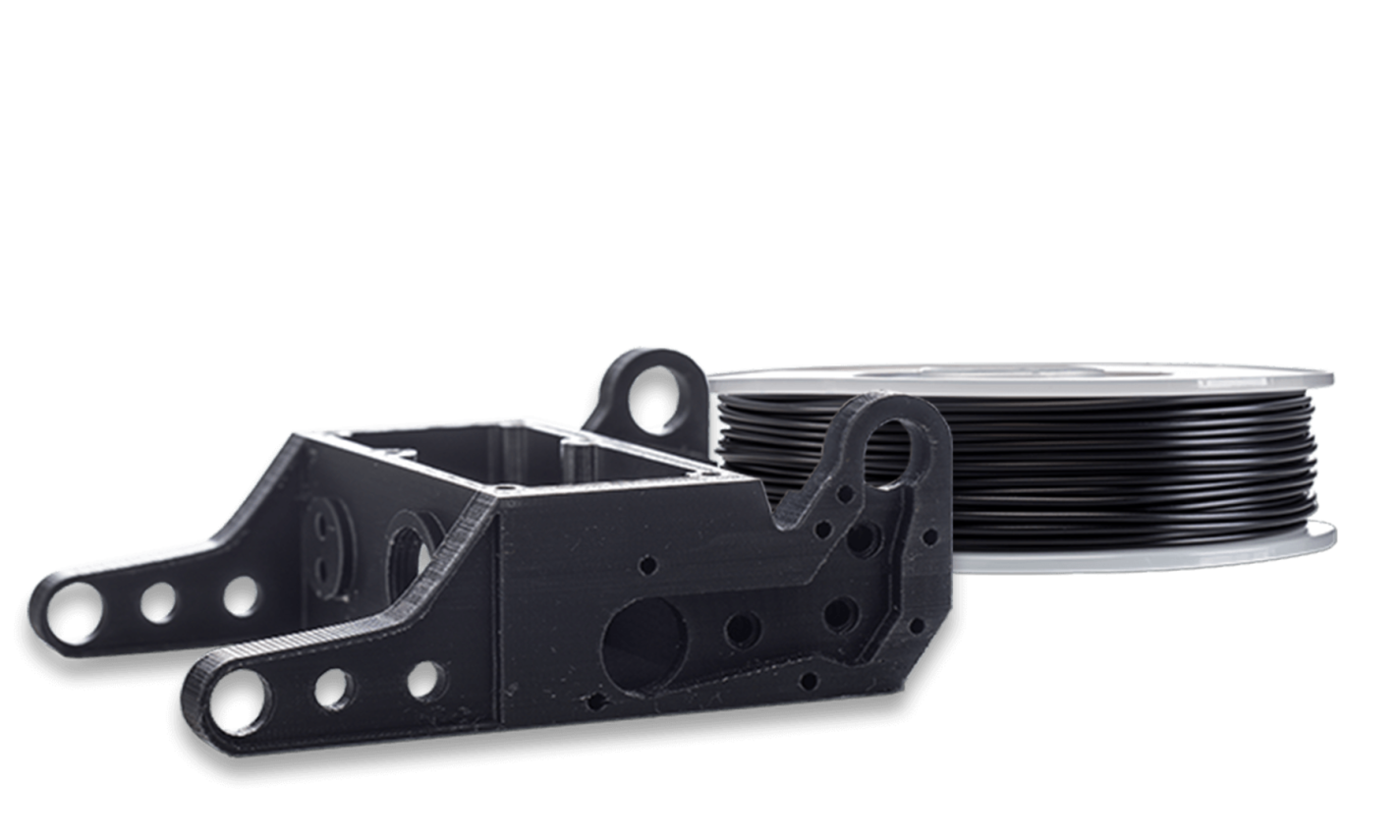

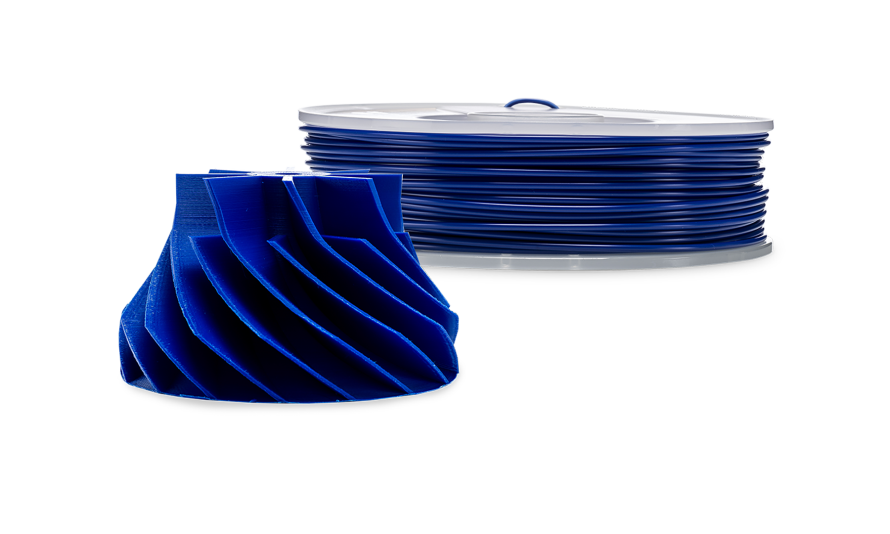

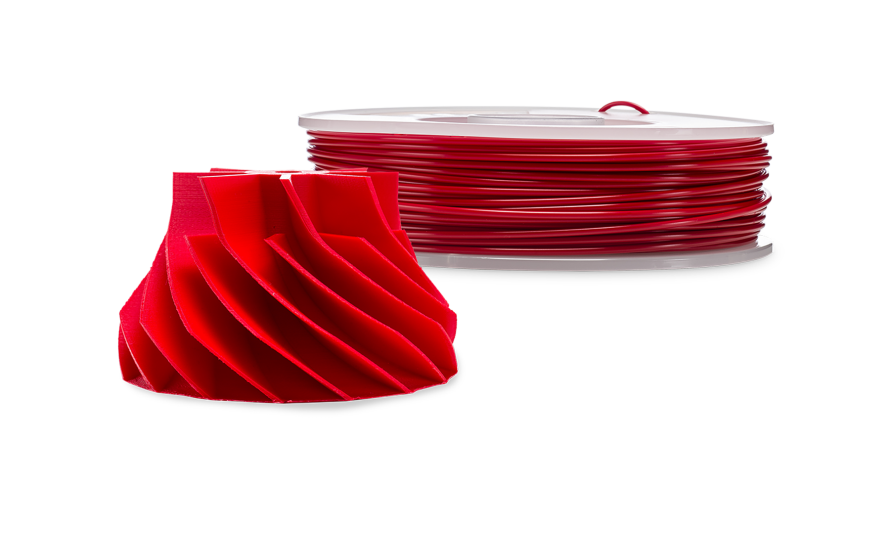

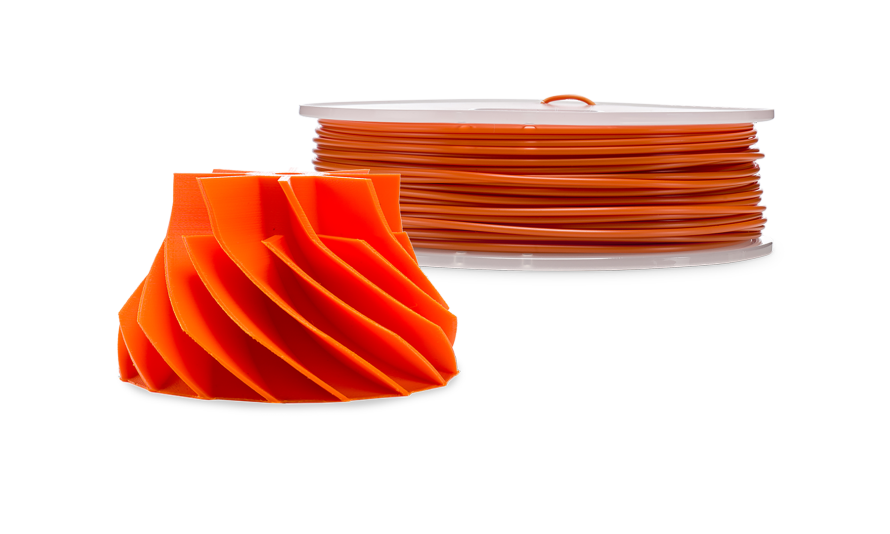

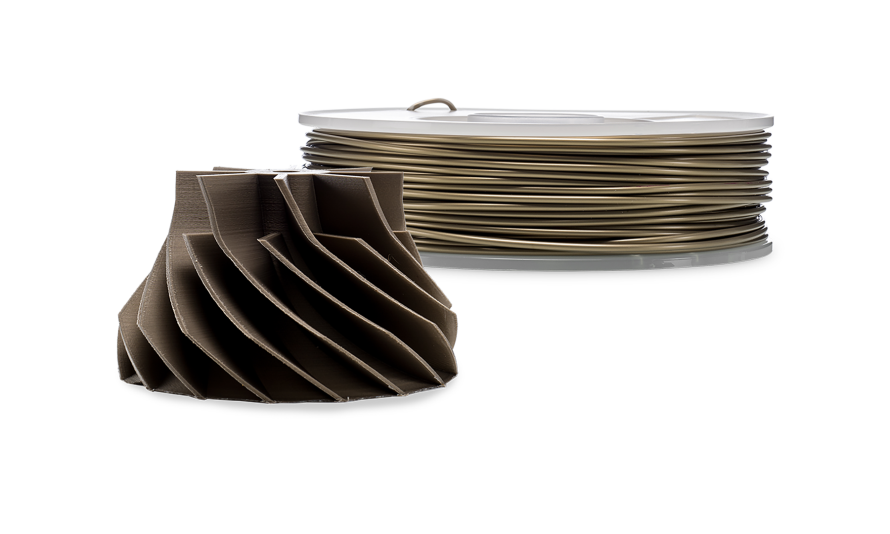

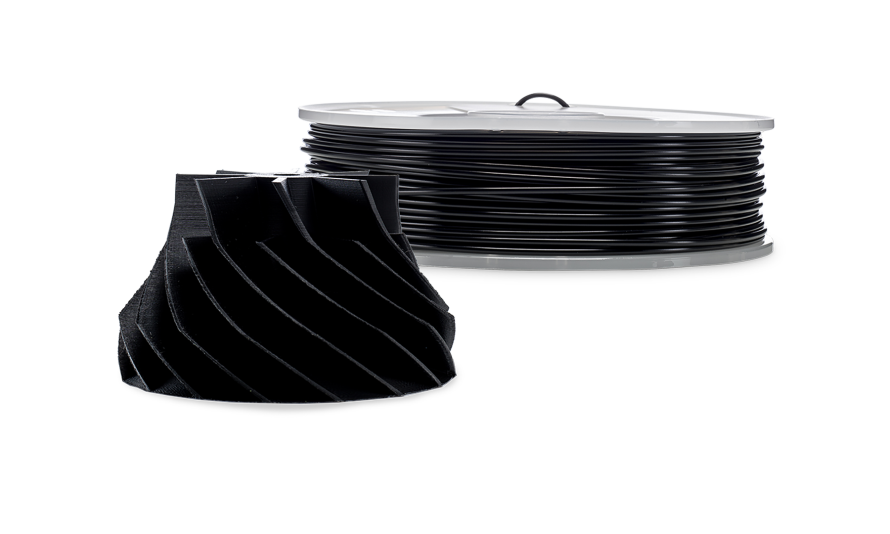

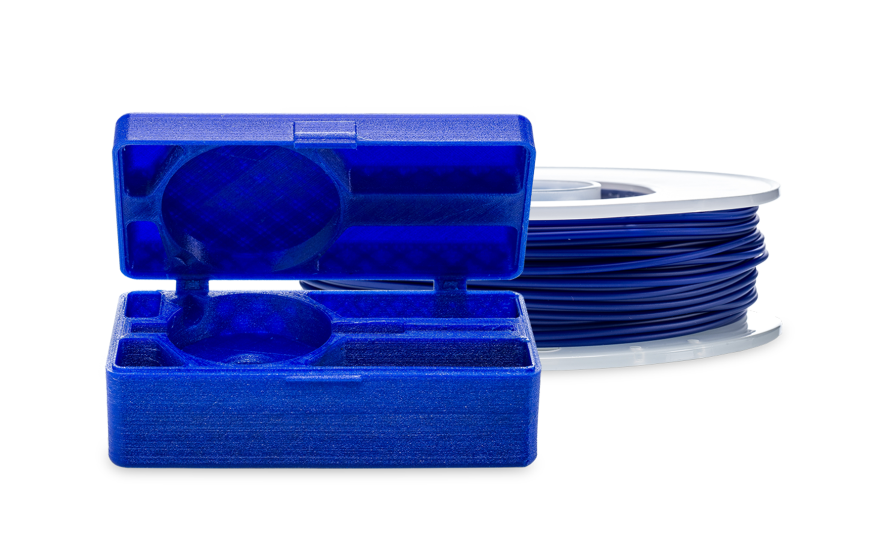

Ultimaker Tough PLA is a technical PLA (polylactic acid) material with a toughness similar to ABS. It is ideal for printing functional prototypes and tooling at larger sizes – without fear of delamination or warping. Our Tough PLA offers the same safe and easy use as regular PLA.

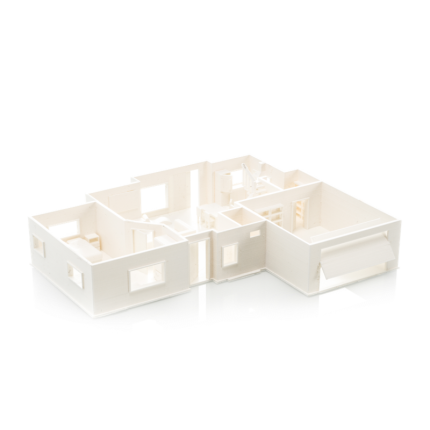

Tough PLA’s impact strength is closer to ABS than regular PLA. This means your 3D printed parts can be used for more functional applications, such as jigs, fixtures, and tools.

When you need toughness in large models, Tough PLA is an easy-to-print and reliable material – ideal for 3D printing with the Ultimaker S5’s bigger build volume.

Designs with intricate curves, fine details, and overhangs can be easily printed with Tough PLA, especially when combined with Breakaway or water-soluble PVA support.

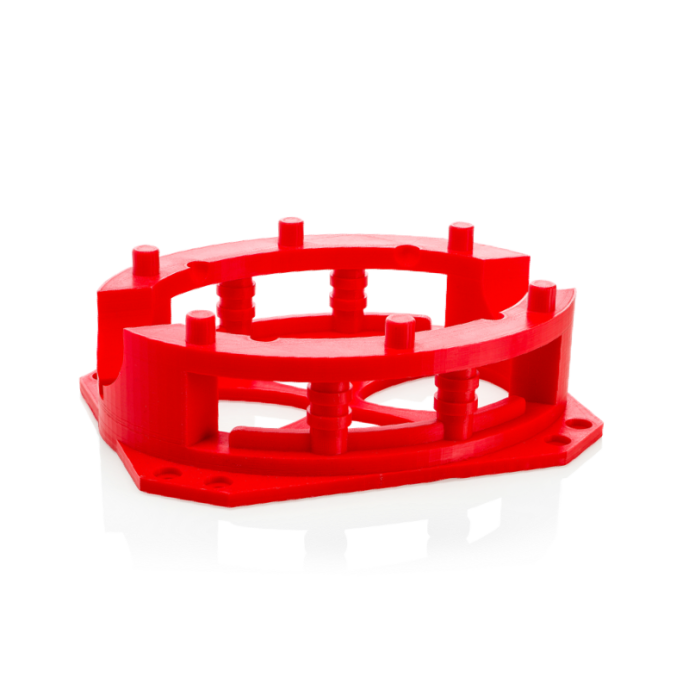

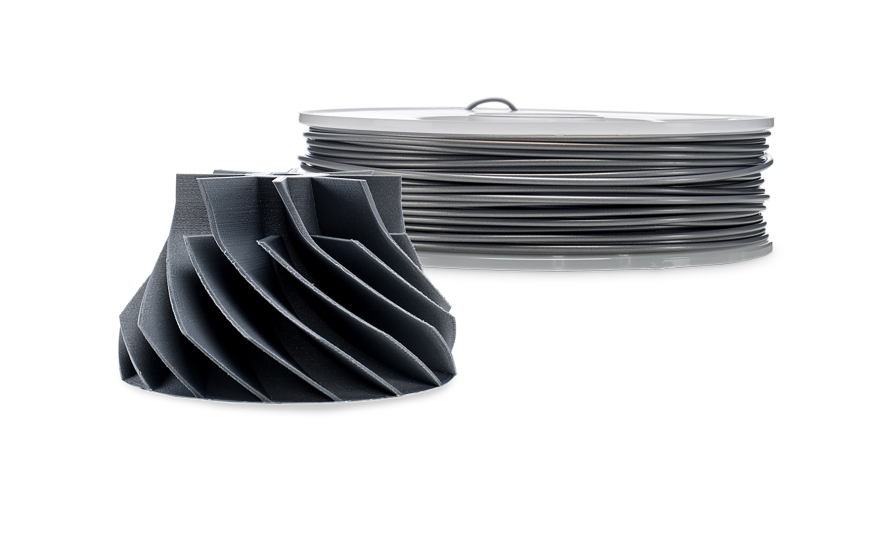

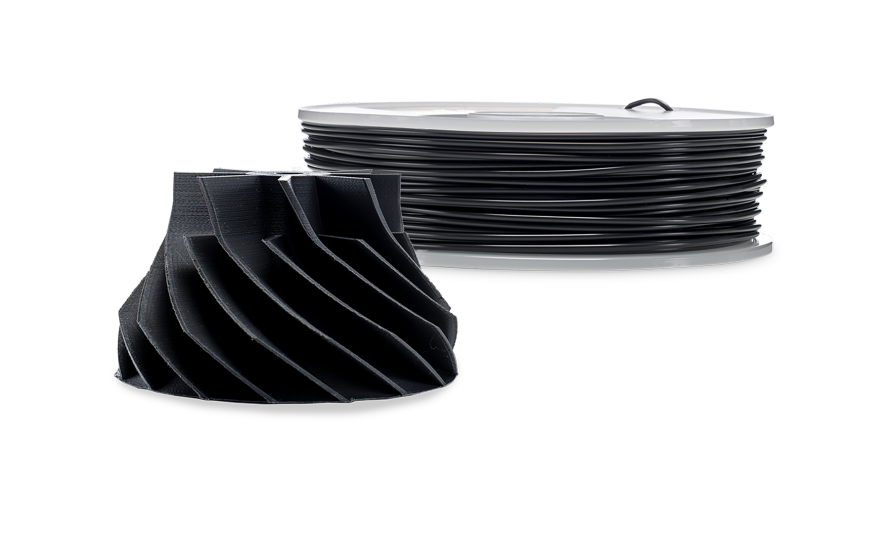

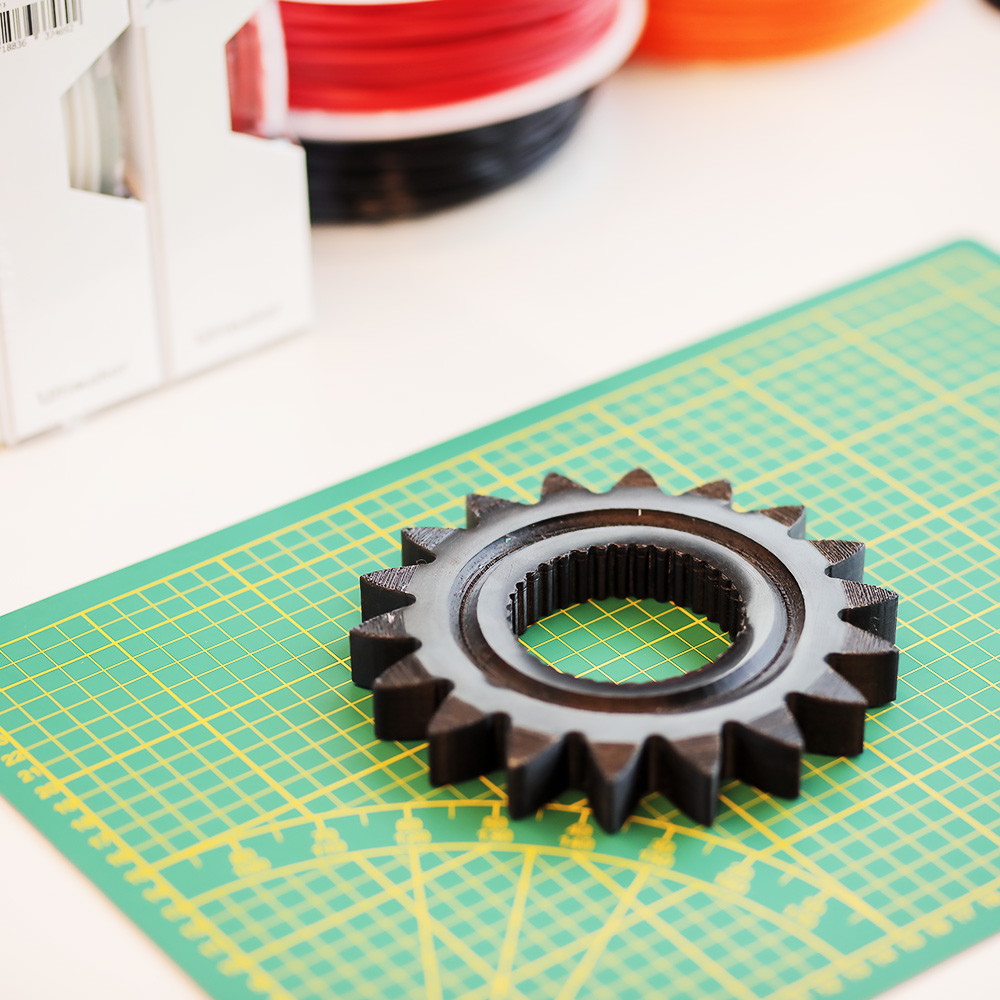

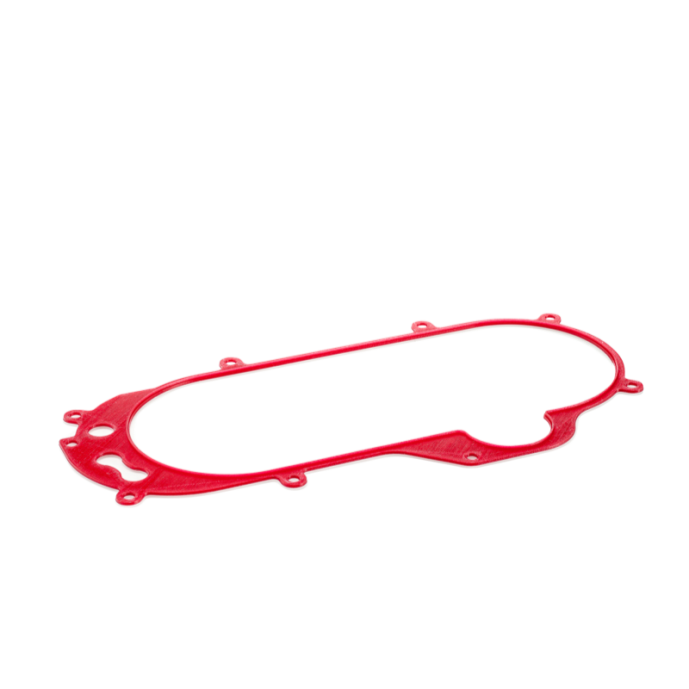

Ultimaker ABS (acrylonitrile butadiene styrene) is formulated to minimize warping and ensure consistent interlayer adhesion. ABS material is a great choice for creating functional prototypes and complex end-use parts.

ABS provides engineers with a low-cost approach for development cycles, allowing them to quickly design, print, and test prototypes before entering full production.

By 3D printing ABS, you can accurately simulate the form, fit, and function of an end-use part’s performance – giving you confidence in the final design

Transition from concept design to manufacturing in days, thanks to the ability of ABS filament to create functional and mechanically strong products.

Ultimaker Nylon is a polyamide grade based on PA6/66. It features reduced humidity absorption and a longer shelf life compared to other nylon filaments. Able to withstand significant mechanical stress, nylon material is a great choice for 3D printing tools, functional prototypes, and end-use parts.

Ultimaker Nylon material has been engineered to resist ambient humidity better than other nylon filaments on the market.

Strong and durable, Ultimaker Nylon is an ideal filament choice for manufacturing end-use parts.

Ultimaker Nylon is a reliable 3D printing filament that can solve multiple mechanical requirements for engineers, designers, and manufacturers.

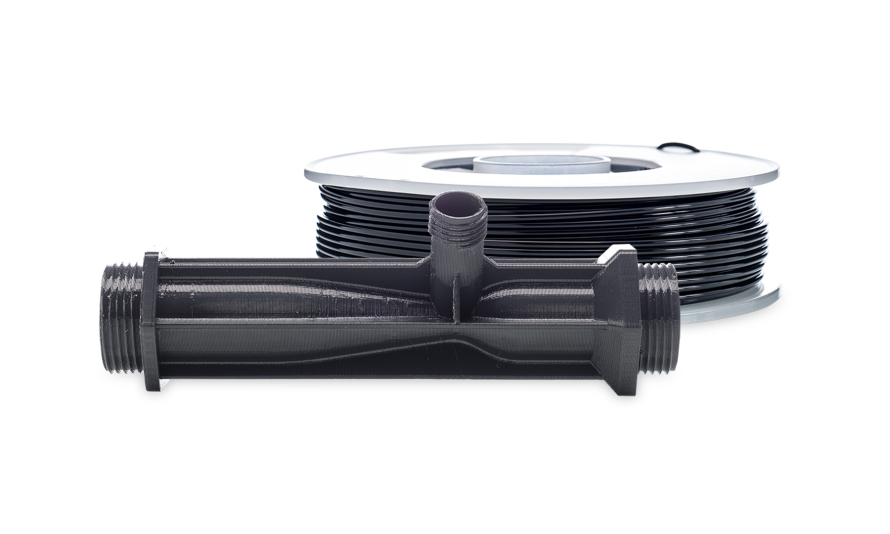

Ultimaker CPE (co-polyester) material is an ideal choice for 3D printing functional prototypes and mechanical parts. This filament is formulated for chemical resistance, toughness, and reliable dimensional stability.

UItimaker CPE material can be used in a range of different situations depending on your performance needs. Print functional prototypes or custom end-use parts.

Ultimaker CPE is a great choice for custom mechanical parts that require chemical resistant properties.

Ultimaker CPE is tough and dimensionally stable, for functional prototypes that require rigorous testing before a production phase.

Ultimaker CPE+ material is chemical resistant with high dimensional stability, with the added advantages of increased temperature resistance and higher impact strength compared to regular CPE.

Ultimaker CPE+ material properties offer increased thermal resistance and impact strength compared to regular CPE, for applications that need to stand up to wear and tear.

With increased toughness compared to regular CPE, Ultimaker CPE+ is an extremely durable material for prototypes that need to stand up to punishment.

Ultimaker CPE+ properties are ideal for custom mechanical parts that need high chemical resistance.

With Ultimaker PC (polycarbonate) material, print parts that are tough, strong, and retain dimensional stability when subjected to temperatures as high as 110 ºC. Our polycarbonate 3D printing material properties make it perfect for printing molds, tools, functional prototypes, and parts for short-run manufacturing.

Ultimaker PC has heat resistant properties that allow it to maintain its form when exposed to high temperatures.

From prototypes to mass manufactured parts, PC material is ideal for a range of functional applications that require extreme toughness.

PC filament is an amorphous polymer, for effective light transmission through 3D printed parts.

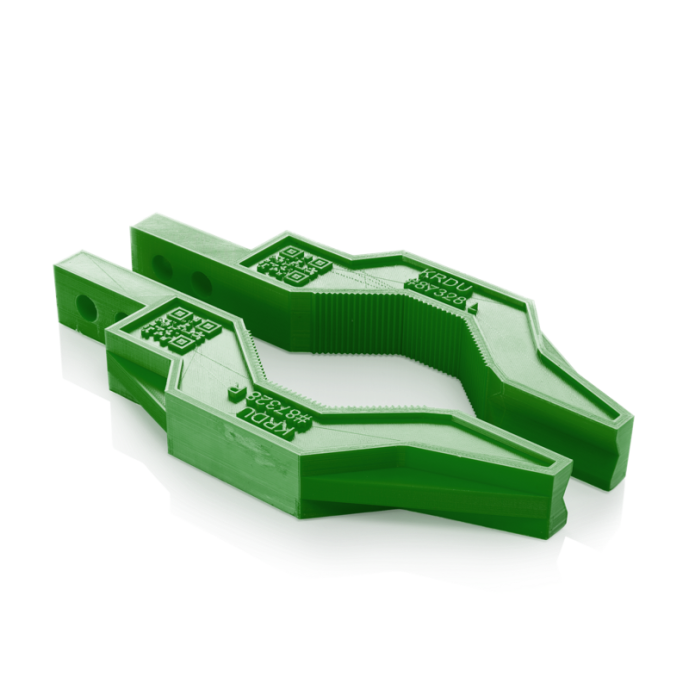

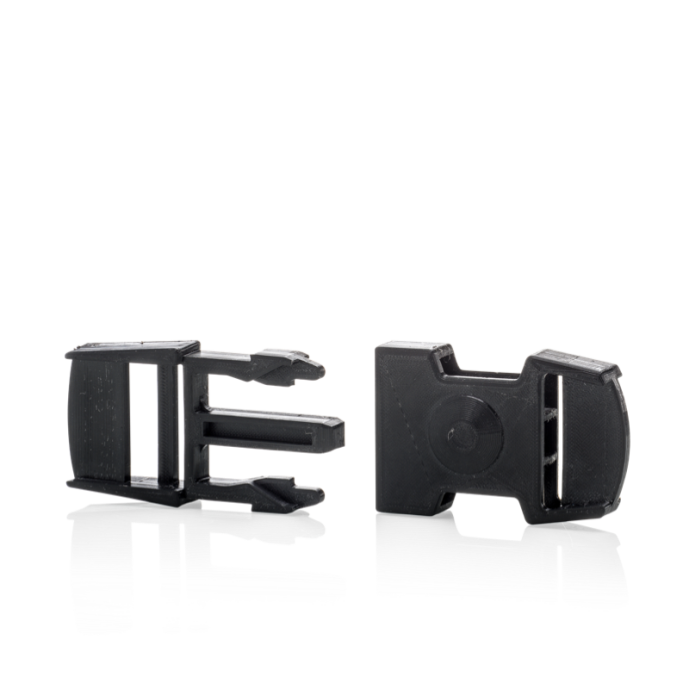

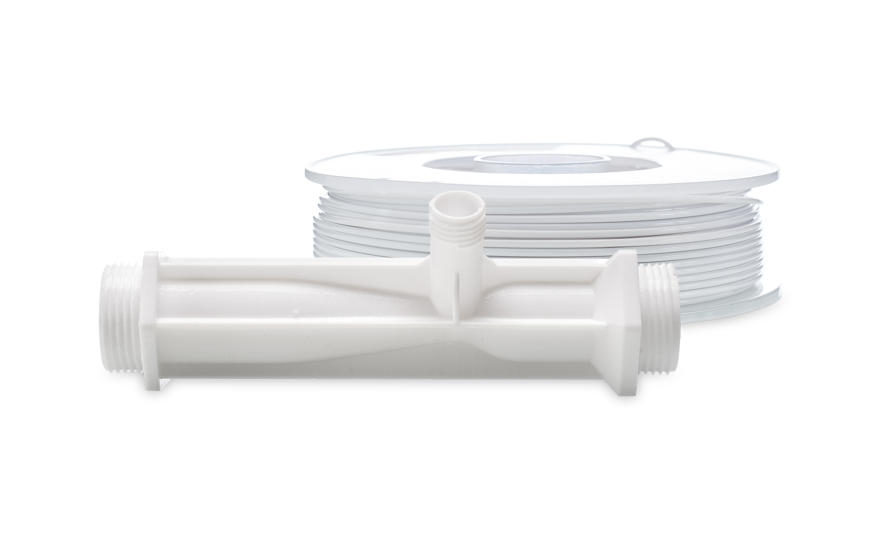

Ultimaker PP (polypropylene) is a durable, chemical resistant material. It has exceptional fatigue resistance, high levels of toughness, and a low-friction co-efficient. From electrical components to living hinges, PP is the go-to material for prototyping and end-use parts.

Ultimaker PP has high fatigue resistance and does not break when repeatedly bent. Clamps and living hinges can remain functional for the lifetime of the printed part.

Polypropylene 3D printing can be used to create functional prototypes that are made from the same material as the end-product.

Ultimaker PP filament is an excellent choice when a design requires translucent properties for aesthetic purposes.

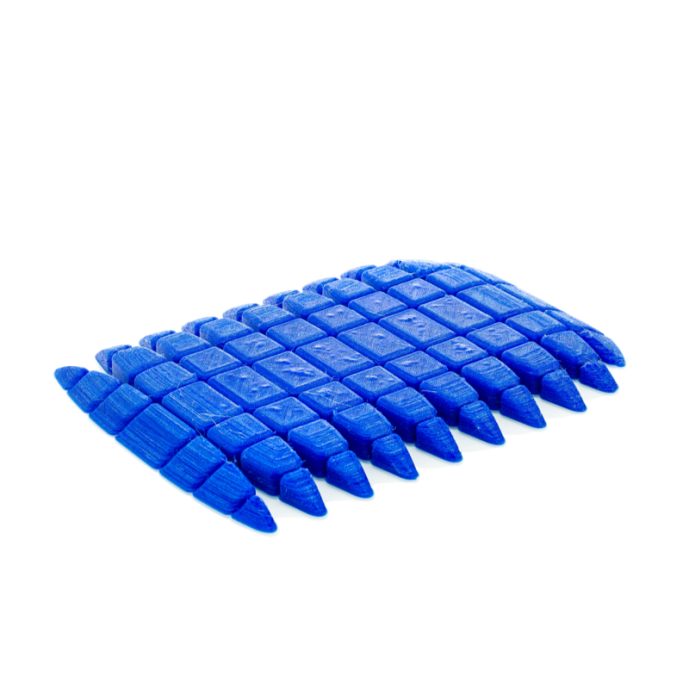

Ultimaker TPU 95A (thermoplastic polyurethane) is a flexible material, making it ideal for applications that demand chemical resistance and the qualities of rubber and plastic. For a seamless 3D printing experience, we’ve engineered Ultimaker TPU 95A to be easier and faster to print than other TPU filaments on the market.

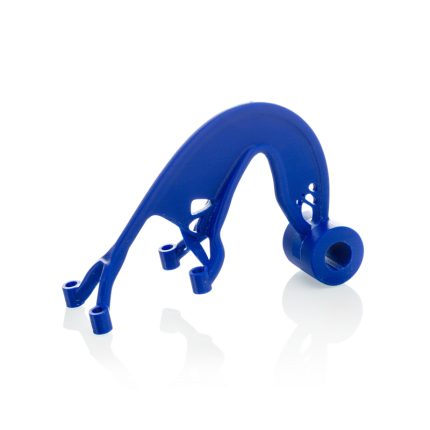

Use Ultimaker TPU 95A’s versatile and flexible properties to conform to an existing part’s surface geometry, or standalone component designs.

Our TPU filament is perfect for 3D printing parts that must retain structural and surface characteristics while subjected to mechanically or chemically harsh environments.

Ultimaker TPU 95A material is suitable for both prototypes and final products, making it possible to test prototypes with the same material properties as the production part.

Ultimaker PVA (polyvinyl alcohol) is a leading water-soluble support material for multi-extrusion 3D printing. It offers you freedom and convenience: to design complex model geometries that require supports, which dissolve away in tap water.

Unlike supports printed with build material, PVA 3D printing support structures reduce the chance of scraping and cutting marks on detailed surfaces.

Preparing a print with PVA gives you the freedom to orient your model in any way possible to customize its strength or aesthetic properties.

Multi-component applications such as ball bearings, ball and socket joints, and caged gear mechanisms can be 3D printed as a complete assembly in a single run.

Ultimaker Breakaway support is easy and quick to remove. It leaves behind a smoother quality finish than other support materials, with no further post-processing needed.

Breakaway allows you to print the overhangs and details you need, with materials not compatible with PVA. For example, it is an ideal support material for CPE or ABS.

Breakaway material is quicker to remove and more affordable than other support materials. It is also easy to store so it stays usable for longer.

Breakaway material has been developed to give reliable adhesion to your build material, but peel away for a smooth and accurate model.